LiquidLocker™ Baffling System

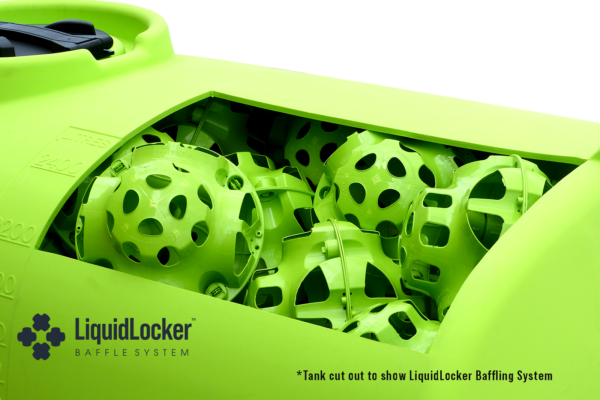

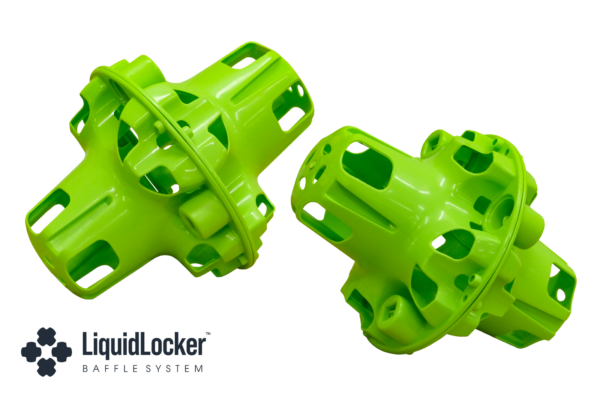

TTi’s LiquidLocker™ baffle system improves load stability during transit of liquids. Due to its irregular shape, the LiquidLocker balls interlock preventing any movement of the balls inside the tank. Whether it’s water, diesel or any other compatible liquids, the LiquidLocker ball baffle system will reduce fluid movement. And, it takes up just 2% of your tank’s total volume! They also significantly reduce mechanical tear and wear by reducing the effect of liquid surge.

Our LiquidLockers are also easy to install, so there’s no need to hire someone to do it for you. Regardless of what type of tank you’re using, our LiquidLockers can be used for a variety of tank materials, including fibreglass, steel, and poly. Browse through our range of LiquidLocker Ball Baffles below. Contact us today on 1800 816 277.

TTi’s LiquidLocker™ baffle system improves load stability during transit of liquids. Due to its irregular shape, the LiquidLocker balls interlock preventing any movement of the balls inside the tank. Whether it’s water, diesel or any other compatible liquids, the LiquidLocker ball baffle system will reduce fluid movement. And, it takes up just 2% of your tank’s total volume! They also significantly reduce mechanical tear and wear by reducing the effect of liquid surge.

Our LiquidLockers are also easy to install, so there’s no need to hire someone to do it for you. Regardless of what type of tank you’re using, our LiquidLockers can be used for a variety of tank materials, including fibreglass, steel, and poly. Browse through our range of LiquidLocker Ball Baffles below. Contact us today on 1800 816 277.

FAQs

Why choose TTi LiquidLocker™ Baffling System

What are the benefits & advantages of having LiquidLockers in your transport tank?

How to set up the LiquidLocker™ into your tank?

How many LiquidLocker™ do I need in my tank?

How is a LiquidLocker™ system installed?

How often are LiquidLocker™ systems used in tanks?

Can LiquidLocker™ be used in any type of liquid tank?

What are the advantages of using LiquidLocker™ over traditional baffle systems?

How do I maintain my LiquidLocker™ system?

Are there specific applications where LiquidLocker™ is especially beneficial?

The Ultimate, Real World Test

3 Highly experienced truck drivers, 1 unbaffled Water Truck and a race track. Watch how the absence of a baffle system creates an unpredictable and dangerous driving experience.

When LiquidLockers are added, see firsthand the improvements on handling, braking and body roll as recorded by Engineer – Jason Underwood.